E.S. Polsen, A.G. Stevens, A.J. Hart. Laser printing of nanoparticle toner enables digital control of micropatterned carbon nanotube growth. ACS Applied Materials and Interfaces 5(9):3656–3662, 2013. [http://dx.doi.org/10.1021/am400148t]

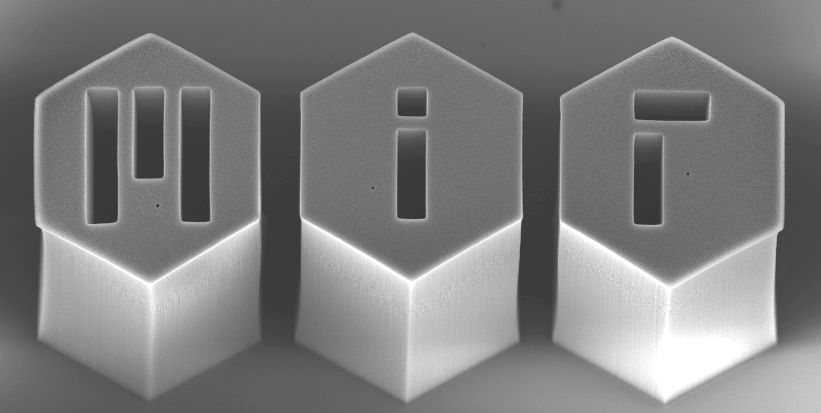

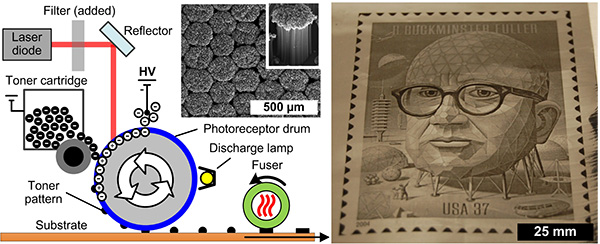

Commercialization of materials utilizing patterned carbon nanotube (CNT) forests, such as hierarchical composite structures, dry adhesives, and contact probe arrays, will require catalyst patterning techniques that do not rely on cleanroom photolithography. We demonstrate the large scale patterning of CNT growth catalyst via adaptation of a laser-based electrostatic printing process that uses magnetic ink character recognition (MICR) toner. The MICR toner contains iron oxide nanoparticles that serve as the catalyst for CNT growth, which are printed onto a flexible polymer (polyimide), and then transferred to a rigid substrate (silicon or alumina) under heat and mechanical pressure. Then, the substrate is processed for CNT growth under an atmospheric pressure chemical vapor deposition (CVD). This process enables digital control of patterned CNT growth via the laser intensity, which controls the CNT density; and via the grayscale level, which controls the pixelation of the image into arrays of micropillars. Moreover, virtually any pattern can be designed using standard software (e.g. MS Word, AutoCAD, etc.) and printed on demand. Using a standard office printer, we realize isolated CNT microstructures as small as 140 um and isolated catalyst “pixels” as small as 70 um (one grayscale dot), and determine that individual toner microparticles result in features of approximately 5-10 um . We demonstrate that grayscale CNT patterns can function as dry adhesives, and that large-area catalyst patterns can be printed directly onto metal foils or transferred to ceramic plates. Laser printing therefore shows promise to enable high-speed micro patterning of nanoparticle-containing thin films under ambient conditions, possibly for a wide variety of nanostructures via engineering of toners containing nanoparticles of desired composition, size, and shape.