Davor Copic, Sei Jin Park, Sameh Tawfick, Michael F. L. De Volder, and A. John Hart. Lab on a Chip 11(10):1831-1837, 2011. [http://dx.doi.org/10.1039/c0lc00724b]

[PDF]

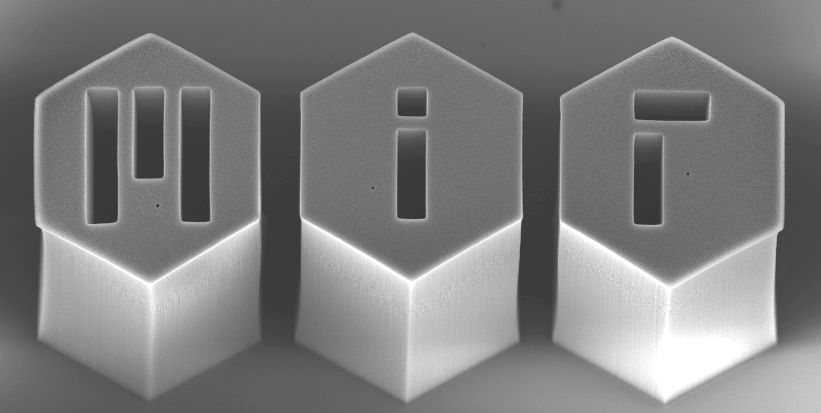

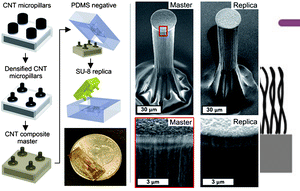

Scalable and cost effective patterning of polymer structures and their surface textures is essential to engineer material properties such as liquid wetting and dry adhesion, and to design artificial biological interfaces. Further, fabrication of high-aspect-ratio microstructures often requires controlled deepetching methods or high-intensity exposure. We demonstrate that carbon nanotube (CNT) composites can be used as master molds for fabrication of high-aspect-ratio polymer microstructures having anisotropic nanoscale textures. The master molds are made by growth of vertically aligned CNT patterns, capillary densification of the CNTs using organic solvents, and capillary-driven infiltration of the CNT structures with SU-8. The composite master structures are then replicated in SU-8 using standard PDMS transfer molding methods. By this process, we fabricated a library of replicas including vertical micro-pillars, honeycomb lattices with sub-micron wall thickness and aspect ratios exceeding 50 : 1, and microwells with sloped sidewalls. This process enables batch manufacturing of polymer features that capture complex nanoscale shapes and textures, while requiring only optical lithography and conventional thermal processing.

Disclaimer: The PDF document on this webpage is provided for educational and personal purposes alone and is subject to copyrights of the publisher.