A.J. Hart, A.H. Slocum, L. Royer. Carbon, 44(2):348-359, 2006. [http://dx.doi.org/![]() doi:10.1016/j.carbon.2005.07.008]

doi:10.1016/j.carbon.2005.07.008]

[PDF]

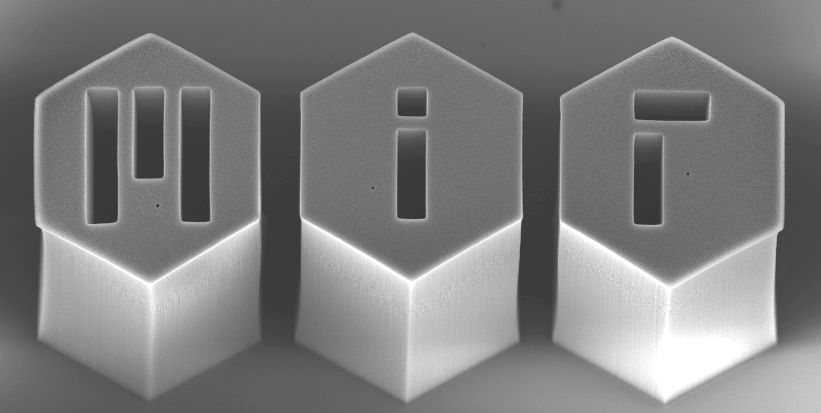

We discuss growth of high-quality carbon nanotube (CNT) films on bare and microstructured silicon substrates by atmospheric pressure thermal chemical vapor deposition (CVD), from a Mo/Fe/Al2O3 catalyst film deposited by entirely electron beam evaporation. High-density films having a tangled morphology and a Raman G/D ratio of at least 20 are grown over a temperature range of 750–900 °C. H2 is necessary for CNT growth from this catalyst in a CH4 environment, and at 875 °C the highest yield is obtained from a mixture of 10%/90% H2/CH4. We demonstrate for the first time that physical deposition of the catalyst film enables growth of uniform and conformal CNT films on a variety of silicon microstructures, including vertical sidewalls fabricated by reactive ion etching and angled surfaces fabricated by anisotropic wet etching. Our results confirm that adding Mo to Fe promotes high-yield SWNT growth in H2/CH4; however, Mo/Fe/Al2O3 gives poor-quality multi-walled CNTs (MWNTs) in H2/C2H4. An exceptional yield of vertically-aligned MWNTs grows from only Fe/Al2O3 in H2/C2H4. These results emphasize the synergy between the catalyst and gas activity in determining the morphology, yield, and quality of CNTs grown by CVD, and enable direct growth of CNT films in micromachined systems for a variety of applications.

Disclaimer: The PDF document on this webpage is provided for educational and personal purposes alone and is subject to copyrights of the publisher.