A.J. Hart, B.O. Boskovic, A.T.H. Chuang, V.B. Golovko, J. Robertson, B.F.G. Johnson, A.H. Slocum. Nanotechnology 17:1397-1403, 2006. [http://dx.doi.org/10.1088/0957-4484/17/5/039]

[PDF]

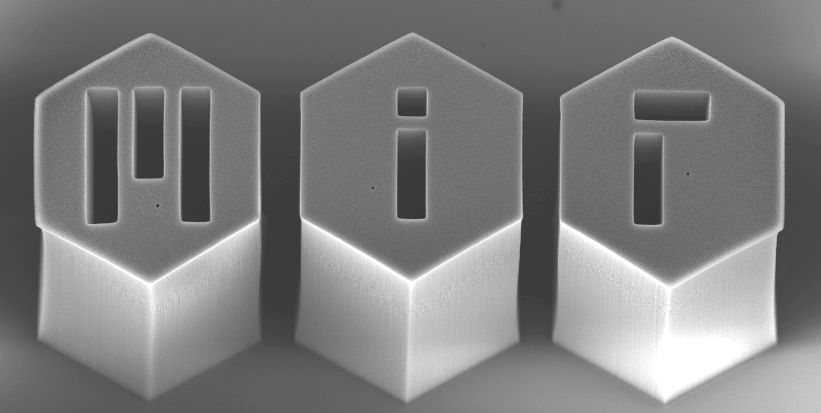

Carbon nanotubes (CNTs) and nanofibres (CNFs) are grown on bulk-micromachined silicon surfaces by thermal and plasma-enhanced chemical vapour deposition (PECVD), with catalyst deposition by electron beam evaporation or from a colloidal solution of cobalt nanoparticles. Growth on the peaked topography of plasma-etched silicon ‘micrograss’ supports, as well as on sidewalls of vertical structures fabricated by deep-reactive ion etching demonstrates the performance of thermal CVD and PECVD in limiting cases of surface topography. In thermal CVD, uniform films of tangled single-walled CNTs (SWNTs) coat the structures despite oblique-angle effects on the thickness of the catalyst layers deposited by e-beam evaporation. In PECVD, forests of aligned CNFs protrude from areas which are favourably wet by the colloidal catalyst, demonstrating selective growth based on surface texture. These surface preparation principles can be used to grow a wide variety of nanostructures on microstructured surfaces having arbitrary topography, giving substrates with hierarchical microscale and nanoscale surface textures. Such substrates could be used to study cell and neuronal growth, influence liquid–solid wetting behaviour, and as functional elements in microelectronic and micromechanical devices.

Disclaimer: The PDF document on this webpage is provided for educational and personal purposes alone and is subject to copyrights of the publisher.